As the number of diabetes sufferers raise, there is a greater focus on insulin which is produced biotechnically. Pump systems which are designed for hygiene and accurate dosing can make an important contribution to efficiency and hygiene in modern insulin production.

Globally, there are around 285 million people who suffer from diabetes according to the estimates of the International Diabetes Federation (IDF) and this figure is predicted to be 438 million by 2030. As a result of this steep rise, there is a greater focus on insulin which is produced biotechnically: this does not just involve improving the quality and effectiveness of the preparations, the production must also be deigned in an ever more efficient way, so that the demand can be met commercially.

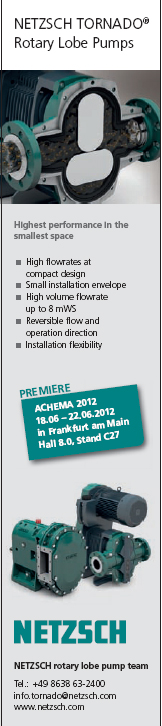

Pump systems which are designed for hygiene and accurate dosing can make an important contribution here, as they have for instance when used at one of the leading pharmaceutical companies in this field. Various design features of these devices which go under the name of NEMO hygienic pumps make cleaning and material handling easier and prevent contaminations in the production process.

High hygiene demands

One of the leading suppliers of insulin analogues has therefore already been using NETZSCH Pumpen & Systeme GmbH's special hygienic progressing cavity pumps for several years to feed plate filters and convey cell mass and suspension. With a view to hygiene, the systems were specifically engineered with a conveying chamber that is as free of dead spaces as possible and designed for CIP or SIP processes.

Depending on the requirement in terms of the level of hygiene, two different types of design are used, one version with a flexible rod to convey the gradient to the filters and one model with a special hygienic joint for transporting cell cultures. This pin joint is rinsed by the medium, which means external lubrication is not needed and a build up of residues is prevented. On the other hand, the flexible rod transmits the rotation of the drive without any moving parts, fulfilling even higher demands for cleanliness and sterility thanks to the absence of gaps. In addition, this design is virtually maintenance-free.

The pumps are fitted with additional cleaning ports and a bypass line in order to meet the requirements of CIP or SIP processes. This means the stipulated flow speed of at least 1.5 m/s can be achieved throughout the system. Moreover, a tangential version of the ports allows the pump to be completely emptied. The materials used are tailored to the prevailing temperatures during cleaning and the specific rinsing fluids. Special versions of the rotors were fitted for insulin production, so that both problem-free product and cleaning runs are possible and perfect performance is achieved.

Contamination security

With respect to hygiene, particular importance is also given to the seals: single mechanical seals with encapsulated wave springs are used here. Where there are higher demands in terms of sterility, there is also an aseptic version with encapsulated double seals which can be exposed to sterile condensate or detector fluid.

Pressure-stable, smooth conveyance

Feeding of plate filters is a special challenge for conventional pump systems in the synthesising process, as they are subject to varying differential pressures depending on the filling level. This fluctuating back pressure as a rule makes it harder to achieve a high consistency level in terms of quantity. NEMO hygienic pumps’ design enables a consistent quantity to be conveyed irrespective of the surrounding pressure ratios. With this design, a helical rotor with a stator forms chambers, as the rotor turns, the chambers move from the inlet to the discharge side, and in the process the pumping capacity can be precisely regulated via the rotation speed. Pulsation and shear forces are avoided and continuous, pressure-stable conveyance is achieved.

This type of conveyance also plays an important role in the particularly sensitive transport of cell mass at various processing stages: whereas major shear forces are applied to the conveyor medium during most other pumping processes, the hygienic pump generates hardly any mechanical stresses for the material being transported. This makes it possible to prevent the cells and cell structures from being damaged or even destroyed during transport. In addition, the pump enables precise conveyance and dosing, which can be adjusted linearly relative to the speed.

High level of availability

Conveyor systems of various sizes and with different rotor geometries were selected for the final production steps, so as to meet requirements in terms of quantity and pressure in each case. Due to spatial conditions and incorporation into the chain of production, both models with a block design and a flange-mounted motor and those in a bearing housing version were used. The NEMO hygienic pumps themselves meet the current EHEDG and QHD directives in terms of their design, as well as the 3A Sanitary Standards.

The first NEMO conveyor systems were installed in insulin production in 2002 and since then additional pumps have been added on several occasions to increase capacity. The systems have demonstrated an extremely high level of robustness here: when the equipment was initially installed, it was assumed that one stator and one and a half rotors would be needed per pump each year. Yet the maintenance intervals have risen to five years before the stator is replaced and 10 years for the rotors.

Conveying systems

increase efficiency and hygiene in insulin production

- by Netzsch Pumpen und Systeme GmbH

- October 30, 2013

- 360 views