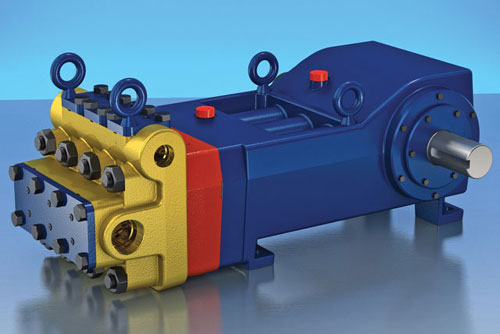

The 'T' Series of sealless high pressure diaphragm pumps developed by Wanner extends the company's Hydra-Cell pump concept into higher flow and pressure capacities. First of the series to be developed, the T8045 sealless triplex pump, is able to deliver liquid flows up to 170l/min at 207 bar.

The series was originally conceived to handle severe pumping applications in the oil and gas industries. Accordingly, field trials have been conducted chiefly in oilfields, where conditions can be particularly demanding. Required levels of performance, the mix and types of liquids pumped, the working environment and the location (often remote from service facilities) together present a formidable challenge.

In an initial application of the T8045, Wanner is working in collaboration with jet pump manufacturer JJ Tech. The Hydra-Cell pump is at the heart of a volume jet lift process in which it delivers 'power fluid' at pressure from surface level to the patented down-hole lift pump. There it is mixed with 'produced fluid' (typically a harsh mix of water, particulate debris, oil and gas) and driven to the surface. The combined fluids are then separated and produced water is reinjected underground, completing the cycle.

Other projected applications in oil and gas and in the process industries generally are likely to be similarly demanding - requiring sustained high performance, often in difficult conditions, with such factors as reliability, safety, energy efficiency and minimal downtime paramount.

The fundamental design of Hydra-Cell pumps, energy-efficient and sealless, enables them to satisfy the two most high-profile pumping concerns in the process industries - energy economy and operational safety.

Their unique combination of features includes: multiple diaphragms manifolded together in a single pump head, giving low pulsation, compact build and enabling in-situ maintenance of the liquid end, sealless design of the pump's liquid end, allowing leak-free operation and dry running; as well as true positive displacement, pressure changes have minimal effect on flow, which facilitates simple VFD flow control, accurate metering and dosing and flexible performance in applicactions such as pressure injection.

Sealless diaphragm pumps

handles severe pumping applications

- by Wanner International

- July 11, 2012

- 451 views