22

22

Digital Plant Asset Management is a topic that often comes up in discussions about process engineering facilities. Today, while intelligent field devices might be the standard, system owners have yet to exploit their full potential. To provide the connectivity needed, Softing offers the right solutions with the smartLink product family.

Author: Dr. Christopher Anhalt, Vice President Product Marketing, Softing Industrial Automation GmbHRaw material scarcity and high energy bills are increasing the pressure on users to optimize their plants and processes. This is where digitalization in process engineering facilities can offer a wide range of options. For system owners, the main advantage here is achieving high productivity at low cost, with efficiency and availability also being decisive factors. Disruptions to production and unplanned system shutdowns are key pain points here, so the idea is not merely to respond quickly to faults if and when they happen but also to identify potential malfunctions at an early stage and take preventive action that will avoid expensive downtime.

The primary tool used for these tasks is Plant

Asset Management (PAM), which aims to give facility owners a comprehensive set of data about the state of their systems. Alongside the process data the control works with, this dataset includes diagnostic data for the individual components as well as asset data that provide information about the installed components and units. To extract useful information from all of this data, it needs to be available to higher-level systems such as the Plant Asset Management system. So how can transparent access be provided to all of these data? Answering this question is a key issue for many plant owners.

Heterogeneity is the rule on the ground

One specific challenge in this context is the

sheer volume of field devices that are in use in the process industry. A further difficulty is a lack of homogeneous interfaces. Traditional connectivity using 4…20 mA is still often found here, with digital integration typically using remote I/O modules via the Hart protocol. A mix of other protocols like PROFIBUS PA or FOUNDATION Fieldbus may also be deployed in the same plant.

This means that, in many cases, users have only been able to integrate some of their field devices with PAM to date. In addition, these structures make field device parameter setting more complex. During operations, making use of these data in Plant Asset Management also requires other steps to be taken, which means that maintenance activities cannot be planned according to demand. The result is a higher risk of an unplanned plant shutdown.

Simple, fast access to Hart field devices

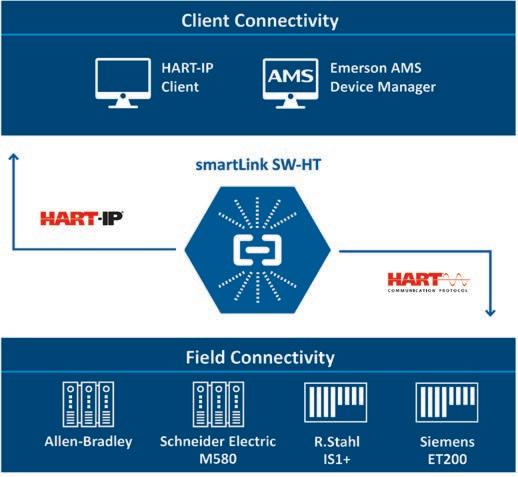

But help is at hand with products from Softing Industrial Automation’s smartLink family. First up is smartLink SW-HT, which provides a software-based Hart multiplexer and an integrated Hart IP Server that facilitates transparent communication over the open Hart IP protocol. The Hart IP Server provides higherlevel Hart IP-compatible applications with simple and secure access to Hart field devices. Typical examples here include Emerson AMS Device Manager, ABB Field Information Manager, or Endress+Hauser Netilion.

As a Docker container, smartLink SW-HT can be used on standard hardware and managed using industry-standard solutions for con-

As a Docker container, smartLink SW-HT can be used on standard hardware and managed using industry-standard solutions for container management. ©: Softing Industrial

tainer management. In the corresponding system environment, the product therefore provides various opportunities for highly efficient and scalable operation. Alternatively, smartLink SW-HT can also be configured as a virtual machine.

In this case, the software multiplexer uses the existing hardware to access Hart field device data and makes these available within the plant network. A lean solution like this offers obvious advantages: apart from avoiding extra spending on hardware, this option also avoids the need for hardware installation or maintenance. Thanks to its browser-based configuration interface, commissioning is also very straightforward with smartLink SW-HT.

To set parameters on the connected field devices, the corresponding Hart commands are sent to the Hart IP Server, which forwards these transparently to the corresponding field devices. Any Hart command can be used without restrictions and smartLink supports many remote I/O modules from leading manufacturers, including Allen-Bradley, Siemens, Schneider Electric, or R. Stahl. Licensing costs are based on the number of Hart field devices to be integrated.

Gateway solution for Hart and PROFIBUS

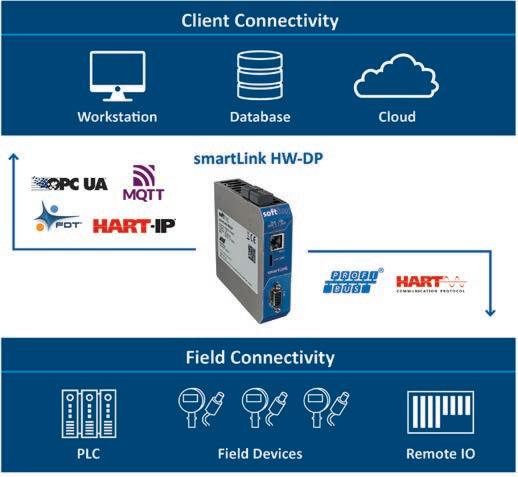

Alongside the software-based smartLink SWHT product, Softing’s smartLink HW-DP provides a hardware solution for accessing field devices. The gateway can act as a PROFIBUS DP master, which provides an access point to a PROFIBUS DP segment and lets existing PROFIBUS segments run inside a digitalized environment and integrate with Industry 4.0 solutions.

Centralized field device parameter setting from the control room is also possible here, which lets users work independently of respective project planning tools. PAM applications are granted access to field device configuration based on the FDT/DTM and EDDL standards, with smartLink HW-DP being configurable for use as a Hart IP Server, OPC-UA Server, or MQTT Publisher. This therefore enables the use of a second, parallel communication channel as specified by the Namur Open Architecture (NOA), which feeds the data to the higher-level Industry 4.0 applications without any need for interventions into the control architecture.

A strong track record

Softing has already used smartLink to suc-

cessfully complete numerous projects. In petrochemical applications, for example, several hundred Hart field devices have been integrated with a PAM system. VMware was used here for the installation of smartLink SW-HT on an IPC used by the Plant Asset Management system.

In a process industry project, more than 60 smartLink HW-DP gateways were deployed to provide an Emerson AMS Device Manager with access to Hart field devices connected via remote I/O modules from R. Stahl. There are also many other examples from different areas of manufacturing where solutions from the smartLink product family are providing users with access to Hart and PROFIBUS devices for their PAM systems. Softing’s smartLink solutions grant access to all of the many kinds of information available from the installed base of smart field devices. This, in turn, gives users access to a data-driven approach to their work that allows them to make informed decisions about optimizing plant operations, ultimately resulting in improvements both to efficiency and availability.

64512 atwww.pcne.eu

Bringingsensorsdirectlytothecloud

TheJJUMO SPE-capableproductportfolioisnowgoingintoseriesproduction.TheinnovativeSPEtechnology hasbeenintegratedinto3newproducts: hydroTRANSS20 (temperature, humidity, CO2transmitter), flowTRANS MAGH20(flowtransmitter)and DELOS S02(pressuretransmitter). Inthisway, individualsolutionstailoredtothe operationalprocesscanbeimplemented.SPEisinterestingforallautomationapplications-andtherebyforallindustries.Manyoperational processesthatneedtoensureahighlevelofavailabilitycanbenefitfromend-to-endEthernetnetworkingthankstoSPEtechnology. Asaresult,theuseofSPEcanavoidstandstillsandenableeven greaterefficiency,whichinturnenableslong-termcostsavings,in manyapplicationscenarios. Importantmeasurandssuchastemperature,airhumidity,CO2,flow,andpressureareforwardedwith highaccuracyandspeedtosuchdestinationsastheJUMOCloud. Forthefirsttime,thisenablescontinuousEthernetnetworkingof thesensorsbasedonthefamiliarautomationpyramidrightdown tothefieldlevel,withoutanymediadisruptioninEthernetcommunication. Eachofthe3sensorsissuppliedviaPoweroverData Lines(PoDL). Cabledistancesofupto1000meterscanbeachieved whenmountingandcablingthesensors.

64280atwww.pcne.eu

Adjustablespeedformodulatingandpart-turnactuators

Rotork announcesthatnew featureshavebeenaddedtothe industry-leadingIQ3Prorange ofintelligentactuators.The newfeaturesincludeincreased speedsfortheIQT3FPro electricmodulatingactuators, independentopen/closespeedsforpart-turnactuatorsand closed-loopcontrolforthemulti-turnandpart-turnactuators. The optionalincreasedspeedfortheIQT3FProelectricmodulating actuatorsisavailableforsizes50,100and125.Adjustablespeed, includingaslowmodeforaccuratepositioningandahigh-speed optionwherefasterspeedsarerequired,makingthemsuitablefor chokevalveapplications.Withtheindependentopen/close speeds,customerscanconfigureIQ3Propart-turnactuators'speed settingsforclockwiseandanti-clockwiserotation.Closed-loop controltakestheon-off/bang-bangcontrolorPIDcontrolmethodologiesthataretypicallyusedinaPLCordiscretePIDcontroller andincorporatesthemintotherange.Multi-turnnon-modulating IQ3Proactuatorsuseasetpointpositioningmethodknownas "bang-bang",whilepart-turnIQT3ProandIQ3MProactuatorsuse thePIDclosed-loopcontrolmethod. TheIQ3Prorangevalve actuatorsarerobust,flexible,andreliableandhaveadoublesealedenclosure,'non-intrusive'commissioning,andpredictive maintenancecapabilitiesusingthein-builtdataloggers.

64366atwww.pcne.eu

ThestainlesssteelIPCsfromthe pro-V-padSTEELIP69kseriesfor systemandprocesscontrolin harshandhygiene-sensitive areasoffoodproductionwillbe presentedatAnugaFoodTec 2024bypproLogistik.Thespecial featuresincludehighimpermeabilityagainsttheingressof particlesandmoisture-especiallyduringsteamjetcleaning.ThestationaryandmobileIPCsare specifiedforanoperatingtemperaturerangeof-30°Cto+50°Caheatingmoduleisoptionallyavailable.Thefood-safematerials arecharacterisedbyhighmediaresistance.Thehousingwithits scratch-resistantandshatter-proofdisplaymadeofthreemillimetrethicksafetyglass(15.6"or21.5")fulfilsallrelevantdesign hygienerequirements.TheIPCsinthepro-V-padSTEELIP69K seriesaredesignedforWindows,Android10andLinuxoperating systemsandcanbecustomisedandfunctionallyexpandedin termsofdesign,processortechnology,screensize,userinterface, connectivityandmuchmore. ThestainlesssteelIPCsareusedfor recordingoperatingandmachinedata,fordataandprocessvisualisationorforqualityassuranceintheproduction,processingand packagingoffoodstuffs.Theycanbeoperatedwithoutrestriction inworkglovesforinputsafetyanduserergonomics.

64347atwww.pcne.eu

Highlyefficientcleaningorhygienicprocessinglines

ThenewAAlfa Laval FreeRotatingRetractor, isahigh-efficiencyretractablecleaning device,providescompletecleaningassurance,enhancingproductsafetywhile boostinguptimeandproductivity. Preparing hygienicvesselsquicklyandeconomically sothatallinteriorsurfacesarespotlessly cleanandreadyforproductioniseasywith theFreeRotatingRetractor.Dynamicand resource-efficient,thisretractableCleaning-in-Placedeviceremainssealedofffrom theproductareaduringproduction,flush withthevesselwall.Thesprayheadslides out,expellingcleaningmediaina310°-upspraypatternacrossthe vesselsurface.Uponcompletionofthecleaningcycle,thespray headretracts,andthevesselisproduction-ready. Theretractor quicklyandeffectivelyremovesresiduesfromtheinteriorsurfaces ofhard-to-cleanvessels,limitingcross-contamination,minimizing downtime,andincreasingproductivity.ItcomplieswithFDA,EU andChinaregulationswhilesecuringgoodmanufacturingand hygienepracticesatdairy,food,beverage,homeandpersonalcare, andotherprocessingfacilities.Forhigh-puritypharmaceuticaland biotechnologyprocessinglines,theFreeRotatingRetractor UltraPureisavailablewitha3.1documentationpackageformetal partsisavailableuponrequest.

64390atwww.pcne.eu

LEWA, a manufacturer of metering pumps and systems, relies on IE5+ motors from NORD DRIVESYSTEMS for high precision applications. They combine a wide control range with outstanding energy efficiency.

For 70 years, the provider LEWA from Leonberg in Baden-Württemberg has specialised in pumps and plants for fluid metering. The world’s leading manufacturer of metering and process diaphragm pumps produces individual, efficient system solutions for its customers. Areas of application are metering requirements, conveyance, mixing and odorising tasks – i.e. mixing of odour-intensive substances, especially with gases – in very different industries: from chemicals to mining. The diaphragm metering pumps of LEWA’s ecodos series are used in sensitive areas such as food or pharmaceuticals, for example for adding additives in the pharmaceutical sector or metering aroma in food. One specific application is the addition of omega-3 oil to baby

food. The ecodos series operates in the socalled low-pressure range, i.e. at a maximum discharge pressure of 20 bar, and with a flow rate of 16 to 1460 litres/hours. This requires pumps that not only allow precise control of the amount and time of addition, but also deliver the ingredients particularly gently.

“For this application, we now also offer our ecodos pumps with IE5+ motors from NORD for wide range control”, Maurice Wirkner, application manager at LEWA, explains. The permanent magnet synchronous motors are either operated as stand-alone motors – i.e. directly flanged to the motor – or with a decentralised frequency inverter.

For the high precision diaphragm pumps of its ecodos series, LEWA GmbH uses the efficient IE5+ motors from NORD DRIVESYSTEMS

NORD DRIVESYSTEMS offers the IE5+ with powers from 0.35 to 3.7 kW. With its fanless design, it is ideal for hygiene-sensitive applications and easy to clean. The optional IP69K protection class even allows the motors to be cleaned with a high-pressure cleaner.

Until now, LEWA had operated its diaphragm metering pumps with classic asynchronous motors or with servo drives including corresponding servo inverters, often combined with stroke adjustment. In the meantime, the pump expert has expanded its selection to include NORD motor technology. For good reason: Permanent magnet synchronous motors are significantly cheaper to purchase than servo drives and they make servo inverters and stroke adjustment superfluous. Classic asynchronous motors, on the other hand, are relatively inefficient outside the nominal speed range and therefore often had to be used in an overdimensioned form. Here, too, the NORD motors are much more efficient alternatives.

“The drive system with the IE5+ is much easier to handle and realises high-precision metering over a very wide adjustment range”, Wirkner emphasises. The NORD IE5+ has a constant torque that can be called up from motor speed 0 rpm (standstill) to the nominal motor speed. This ensures a particularly smooth start-up of the system, which protects the sensitive products LEWA customers work with in the food and pharmaceutical sectors.

The extreme control range and the short-term high overload capability of the IE5+ motors

With its smooth, fanless design, the efficient IE5+ motor is ideal for applications in the food and pharmaceutical industry

from NORD often make the use of several pumps for different flow rates superfluous for LEWA’s customers, which results in a reduction of the drive variants in the overall system. This minimises administrative costs and streamlines production, logistics, storage and service processes. The outstanding 95 percent energy efficiency of the IE5+ motors adds to this.

“With its high energy efficiency, this drive system provides many advantages for our customers and thus also for us as a future-oriented pump and system provider”, Maurice Wirkner explains.

Development accompanied as a project partner

LEWA accompanied the development of the highly efficient IE5+ motor as a kind of project partner. “We were already able to test the motor together with our pumps as a system during the prototype state and thus gain initial experience”, application manager Wirkner says. Technical sales, product management and the NORD service were able to provide very good and competent support here. “We are also very satisfied with the cooperation with NORD for the previous orders, especially with the flexibility.”

The cooperation between LEWA and NORD is definitely to be continued. The next project is already planned: The partners are developing a trade fair demonstrator of a pharmaceutical metering pump with IE5+ motor and decentralised NORDAC ON+ frequency inverter from NORD, which illustrates the advantages of the wide-range control in metering with the LEWA ecodos diaphragm metering pump.

64653 at www.pcne.eu

PCN Europe spoke to Mark Pontin, Managing Director of Resolve Optics about the challenges for lenses in optical material inspection and sorting applications.

PCN Europe: What experience and expertise does Resolve Optics bring to materials inspection and sorting – a common task in many industries?

Pontin: Drawing upon a highly experienced team of optical designers and engineers – Resolve Optics has a proven track record in designing and producing high performance custom lenses for materials inspection and sorting applications. In the last few years, we have received several major orders for instrument optimised versions of our Model 363-000 – a 16mm Short Wavelength Infrared (SWIR) lens for inspection and material sorting applications. Our aim is to provide a fast and flexible optical and mechanical design assessment on all projects. A project engineer is assigned to closely liaise with customers at all points of a development to ensure complete satisfaction with the final product. The experience of our design staff combined with cutting-edge Computer Aided 3D modelling ensures that top performance is designed into all our lenses and optical systems. Advanced optical manufacturing and CNC machining technology is used to produce high quality components. In assembly, our experienced workers build complete assemblies with care and attention to detail. All products are tested before leaving our factory to ensure complete satisfaction. It is this blend of skills,

Mark Pontin, Managing Director of Resolve Optics

Mark Pontin, Managing Director of Resolve Optics

experience and flexibility that have established Resolve Optics as a leading manufacturer of special lenses and optical products for materials inspection and sorting.

PCN Europe: What are the advantages of using Short Wavelength Infrared (SWIR) rather than Visible lenses in a materials inspection or sorting system?

Pontin: The SWIR region covers wavelengths between 0.7 and 1.9 µm. Compared to imaging sensors operating in the MWIR or LWIR regions, those that capture SWIR’s shorter wavelengths deliver images with higher resolution and stronger contrast, which are key criteria for inspection and sorting applications. SWIR imaging can also highlight features and defects that visible imaging systems cannot. Because water absorbs strongly at SWIR wavelengths it means that objects or features with a high moisture content appear black in images captured using a SWIR camera. Consequently, SWIR imaging systems are widely used to determine moisture content and bruising damage in fruit, produce and grain.

PCN Europe: Why when the cost of an off-the-shelf lens is typically lower – should material sorting and inspection instrument developers consider a custom SWIR lens?

Pontin: An off-the-shelf lens will almost always provide a cheaper option, therefore one of the first steps we take with any new project, is to determine if a suitable off-the-shelf solution is available. However, using an off-the-shelf SWIR lens typically forces you to accept compromises such as a reduction in optical performance, achievable resolution, a larger less attractive product, shorter product life and no control over security of supply. By contrast, demand for custom versions of our Model 363-000 SWIR lens that exactly meet the needs of individual customer applications are rising dramatically. This is not just because of performance advantages but also these custom SWIR lenses provide security of supply and exclusivity to a solution that can give you a market advantage.

PCN Europe: How are inspection and sorting system instruments evolving and what challenges does this pose to developing optimised optics for them?

Pontin: The evolution of materials inspection and sorting systems tends to be driven by new sensors. Sensors are improving all the time, often driven by customer desire for different formats and higher resolution. This trend is the major driving force behind the growth in demand for SWIR lenses that meet the demands of high-resolution Indium Gallium Arsenide (InGaAs) sensors. Our Model 363-000 SWIR lens design uses carefully selected glass types and AR coatings to ensure maximum transmission, colour correction and best image quality throughout the SWIR waveband. Operating at f/1.6, with less than 2 per cent geometric distortion, the Model 363 lens produces a clear crisp 12.8mm diameter image.

While we look to future proof an optical design as much as possible it is very difficult to account for format changes without making the initial design more expensive than is required for the application. Therefore, if a material inspection or sorting system sensor format

changes significantly you will typically require a new lens design.

PCN Europe: Can you describe a typical project process and duration when a customer wanting to improve their material inspection or sorting capabilities contacts you?

Pontin: As I have previously mentioned - the first step is for our design team to discuss the customers application to see if an offthe-shelf optical solution is available. If a lens or optical system with the required attributes is not yet available, we would work with the customer to write an optical specification, ensuring that the final agreed version meets and or exceeds the customer application requirements. We then undertake some initial design work to identify what is possible and to enable us to confirm budgetary costing. Then from the point of the customer placing an order it typically takes between 5 to 6 months for the first application specific custom lenses to be supplied.

PCN Europe: What testing systems and procedures do you employ to ensure the quality of the lenses and optical systems?

Pontin: Resolve Optics carries out 100% inspection and optical testing prior to any lenses being shipped to a customer. All our optical testing is carried out on a state of the art fully automated MTF testing system This equipment allows us to qualify that each lens exceeds the designated customer specification requirements for resolution, distortion, FOV and register. Due to the automated nature, and the accuracy of the test set-up, we can ensure that each lens is tested under the exact same conditions. Any lenses that do not pass this testing are then reworked and retested. This guarantees that every lens that leaves Resolve Optics UK facility meets or exceeds the specification as agreed with the customer.

PCN Europe: Thank you for your insights.

64509 at www.pcne.eu