The grapevine is one of the oldest cultivated plants of the world. In order to keep alive the ancient tradition, people increasingly use centrifugal separation technology for modern and economic wine production.

During the whole winemaking operation, clarification plays an important role. Thus an efficient clarification system often determines the taste, aroma, and character of the wine and therefore its overall quality and its market value.

Decanters in wineries are used everywhere where liquids with a high solids content have to be clarified. The clarification of the freshly pressed grape juice (must) is one of these applications. But not just economic aspects have to be considered, quality is a crucial factor as well.

The trub (solids) content of the must depends on pre-treatment such as grape gathering and grape transportation. Trub is automatically generated when the grapes are treated. Generally, machine-gathered grapes contain more trub than hand-gathered ones due to high mechanic forces. The press system also influences trub quantity. Must produced by screw extrusion presses is inclined to contain more trub than must produced using membrane presses.

Traditionally, must clarification is done by static sedimentation and subsequent kieselguhr filtration of the sedimentation trub using vacuum rotary filters. Compared to centrifugal decantation, this procedure results in longer contact of the must with trub particles. Trub particles, however, may have negative effects on the must since they often contain much phenol. In the worst case, they may also cause fermentation because of wild yeast. Decanters are able to quickly treat must residues with high solids content due to centrifugal acceleration.

Moreover, traditional kieselguhr filtration results in high costs for waste disposal and challenging maintenance, as well as high expenses for filter additives, cleaning, and monitoring. It also results in potential health risks (the WHO considers kieselguhr particles to be carcinogen).

While investment costs for a decanter are indeed higher than for vacuum rotary filters, the low operating costs of a decanter offer decisive economic advantages. The decanter needs significantly less preparation and cleaning time than vacuum rotary filters since decanters do not need filter additives. Therefore, there are no costs for waste disposal while Kieselguhr is classified as hazardous waste, resulting in continuously increasing disposal costs. As the decanter discharges a very dry cake, the solids can be used as fertilizer for the vineyard and thus be reintroduced into nature.

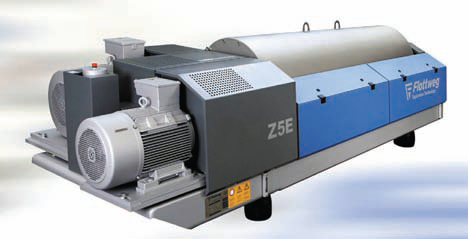

Optimal yield, excellent quality, trouble-free environmental compatibility, and cost effectiveness are decisive factors for must clarification. Flottweg decanters work automatically and continuously to reduce processing time and allow for safe and efficient treatment. Furthermore they are designed for the high hygienic demands of wineries because all product-wetted parts are made of high quality stainless steel.

The must is fed through a stationary pipe into the feed zone located in the center of the scroll. The product is then accelerated circumferentially and delivered through distribution ports into the bowl. The bowl has a cylindrical/conical shape and rotates at a pre-set speed optimal for the application. The must rotates with the bowl at the operating speed and forms a concentric layer on the bowl wall. The solids contained in the must are deposited against the bowl wall by centrifugal force. The scroll rotates at a slightly different speed than the bowl and conveys the deposited solids toward the conical end of the bowl. This differential speed determines the residence time of the solids in the bowl. Settled solids are ejected through ports at the conical end of the bowl.

Must is discharged via an adjustable impeller. This permits quick and precise adjustment of the pond depth during operation to accommodate changing conditions without switching off the decanter.

Since the must is discharged of the decanter under pressure, a discharge pump is not necessary. The clarified must normally contains solids of <1% v/v. Subsequent flotation allows the elimination of particles which cannot be separated from the must because of the small density difference. Decanters may also be used for treatment of flotation trub or wine recovery from tank bottom after fermentation.

Quality is more important than ever in the winemaking process. Today, disk stack centrifuges for fine clarification have become indispensable in wineries in order to give the features which characterize a good wine: wellbalanced, full of character, and full-bodied. The clarifiers of the AC series are particularly suitable for wine clarification since the latest knowledge of disk stack centrifuge construction and the requirements for hygienic design have been perfectly combined. Decanters and disk stack centrifuges are applied in many different ways in wineries. The combination of decanters and disk stack centrifuges ensures a very efficient, cost-effective clarification of wine and must.

Wine is culture, tradition, experience and emotion. Its quality, color, and clarity are decisive sales arguments. Flottweg decanters and disk stack centrifuges especially designed for must and wine clarification make an essential contribution to this goal.

Centrifugal Decantation in the Wine Production

The grapevine is one of the oldest cultivated plants of the world.

- by Flottweg SE

- February 1, 2009

- 1264 views