Compressed air generation is equivalent to about 10% of industry's total electricity usage, rising to 30% in some sectors. A compelling reason for companies to investigate the potential for energy saving in this area.

Recently, industry specialists have given added momentum to the argument by calculating that the operating costs of running multiple compressed air installations without some form of management control can be more than 30% higher than they should be.

Cascade Control

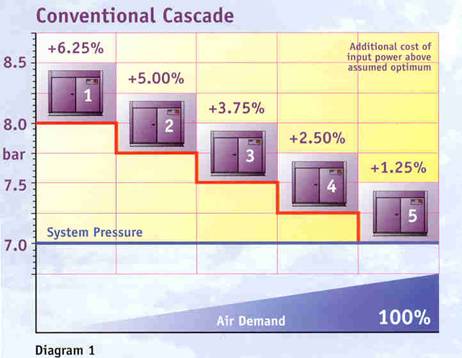

Traditionally, the control of multiple compressed air installations has been achieved using a Cascade controller. The controller is meant to ensure only the number of air compressors required to satisfy demand are running, employing a traditional principle of cascaded pressure banding. As compressed air demand rises and line pressure begins to fall, compressors with lower pressure bands come into operation increasing system output. When compressed air demand falls and line pressure rises, only the required number of compressors with higher-pressure bands will operate. This sounds fine in theory, but in practice conventional cascade controllers, or controllers based on cascade principles, have a number of inherent drawbacks. These can be summarised as problems with Pressure Optimisation, Control Optimisation, Compressor Selection, Monitoring and the mechanical reliability of some cascade controllers.

Pressure Optimisation

Firstly, by using a number of pressure switches each with a typical 0.5 bar differential the controller forces the system to produce compressed air at a pressure above that required (see Figure 1). Only the compressor with the lowest pressure band setting will be operating near optimum required system pressure. This has a dramatic effect on overall system efficiency when you consider that a 0.5 bar decrease in system operating pressure will reward an additional 5.25% reduction to the overall cost of electricity consumed by the system.

Control Optimisation

A conventional cascade arrangement generally does not allow for 'fine tuning' of either compressor utilisation and / or air system pressure and demand changes; such as shift pattern changes, weekend shutdowns or low demand periods. This, again, can have a dramatic effect on overall system efficiency. For example, by shutting a compressor system down when it is not required (weekends, holidays & non-production periods) typical air leakage rates of as high as 18% of annual system output can be overcome, enabling reductions in the overall cost of electricity associated with the compressed air system.

Compressor selection

With the cascaded pressure switch method of selection, compressors are managed in a very basic and routine way to even out utilisation. Typically on a weekly or monthly rotation of selecting compressor 1, 2, 3, 4, moving to 2, 3, 4, 1 and so on. Additional factors may influence and limit the user ability to cascade compressors evenly such as varying compressor sizes and site air demand pattern changes. This restricts the users ability to select the optimum compressors to match air demand at a given point in time resulting in increased system energy costs.

Monitoring capability

Traditional cascade controllers are generally not able to monitor the compressed air system and provide diagnostic data for the user. Any system efficiency deterioration can go undetected and result in increased operating costs.

What are the alternatives?

A specialised compressor control package such as EnergAir's Enercon Air Management System can provide an effective solution by combining effective system monitoring and reporting with precise, intelligent compressor control. Savings can be gained from almost any multiple compressor installation rated at 4kW and above. However, results have shown that 30kW is the usual baseline from which savings are of sufficient magnitude to deliver acceptable payback periods typically from 9 to 18 months.

An compressed air management system reduces compressor energy consumption by closely matching system pressure to demand and reducing off-load running or idling of compressors. The control is implemented in a number of ways depending on the installation, including the use of a variable speed drive (VSD) optimised for compressor control where necessary. An ‘Enercon’ management system controller for example will also ensure that all the compressors on any one ring main, regardless of their make, type or capacity, operate cohesively and more importantly, efficiently.

Effective downstream system monitoring is also an essential part of the package. Sensors are fitted at relevant points throughout a system and the recorded data is presented by the EnerSoft air management software. The software displays live information on equipment status and system pressure, while providing accurate metering of power consumption in kW/hours, air production volume in m3 and efficiency in kW/m³. EnerSoft can also be used to produce regular performance reports for internal appraisal; the function is a built-in feature of the software and is extremely easy to use.

Problems with traditional cascade control

on compressed air installations

- by Energair Solutions Ltd

- September 13, 2010

- 602 views