The history of medicine is as old as humanity itself. A discipline that largely consisted of monastic herbal lore in Europe from the Middle Ages onwards has in the 21st century become a high-tech process that, due to its complexity, involves an abundance of related data—and this data volume is continuing to grow: “As a result of Industrie 4.0, it is also becoming increasingly important to allow decentralized access to information and control functions. And pharmaceutical production is no exception. Increasingly, companies are relying on multipurpose plants that are designed for the most efficient possible production of various medicinal products,” explains Business Development Manager Stefan Sittel. His colleague, Dr. Marc Seißler, Product Portfolio Manager, adds: “Networked HMI systems are essential for achieving sustainable, efficient manufacturing in the pharmaceutical industry. However, they must also comply with regulatory requirements for pharmaceutical production, the GMP (Good Manufacturing Practices) directives, and, in some cases, explosion protection directives.”

Fine Chemistry for a Powerful Effect

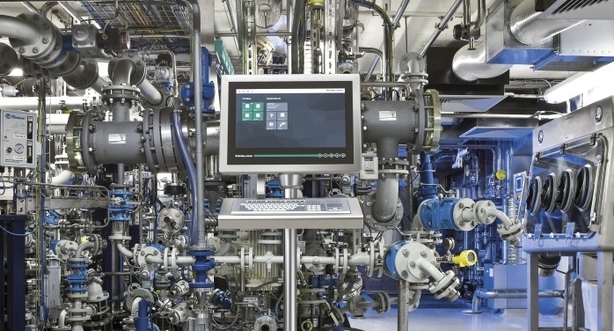

If you were to accompany medications on a typical journey through their manufacturing process, you would encounter various Pepperl+Fuchs operating and monitoring systems along the way that solve this problem. The spectrum of operating locations begins with the upstream suppliers from fine chemistry, who provide the basic materials to the pharmaceutical manufacturers in what is known as the “upstream phase” of pharmaceutical production. To obtain these substances, every detail—such as the purity of the various components, the storage temperature, and the pH value—must be correct. Only in this way can it be ensured that they will achieve the desired effect during the subsequent synthesis of the active ingredients. The latest development from Pepperl+Fuchs in this field can be seen in the form of VisuNet GXP—a thin-client-based remote monitor that can be used to display process information and control functions and is fully aligned with the needs of fine chemistry. It is built to be resistant to liquids, dirt, bacteria, and aggressive cleaning processes, while its extremely lightweight and modular design allows for high flexibility in the field. In addition, the VisuNet GXP is suitable for the potentially explosive atmospheres that occur in these process stages due to dust or detergents and solvents containing alcohol. During batch or dosage control, it reliably displays information transmitted via Ethernet from the control system or MES—directly in ATEX Zones 1 and 21 or Zones 2 and 22. “Whether it is connected with conventional PC workstations and servers via the network infrastructure or used on future-oriented, virtualized PCs and servers plays no role in the integration into the automation architecture. Our new firmware VisuNet RM Shell 4.1 supports the latest remote services such as Microsoft® RDP 8.1 or Emerson’s DRDC and therefore both approaches,” Sittel explains.

Under Open Skies

Pepperl+Fuchs has also equipped its other highly specialized, Ethernet capable operating and monitoring systems with the RM Shell 4.1. This includes the VisuNet IND product family, which is used in tank farms for pharmaceutical substances. In these potentially explosive atmospheres—corresponding to Zone 2 and Class I, Div. 2 respectively— where basic chemicals from fine chemistry are temporarily stored, the filling and emptying of the tanks must be monitored and controlled. Wind and weather also take their toll on the equipment used. “The VisuNet IND shows process-critical information about fill levels and temperatures on the display in a clear format.

It therefore helps the tank farm personnel make decisions and provides a real gain with regard to process safety and availability. When used in conjunction with integrated identification systems from our portfolio, it can also provide reliable identification of truck drivers making deliveries and of loading orders,” Sittel explains. “As outdoor solutions, remote monitors from the VisuNet IND family have displays that are visible in daylight and are designed to be rainproof. The temperature range in which they can be operated extends from a wintry –20°C to +50°C in the summer sun,” says Seißler, describing the design features. As for the software level, he says, “The Ethernet connection of HMIs is particularly advantageous in outdoor areas. Thanks to digital communication between the remote monitor and host system, consistently high image quality can be maintained without the comprehensive configuration required for the formerly prevalent analog KVM systems. Additionally, the possible transmission range via the network infrastructure is not limited as with a KVM system.”

Hand in Hand

During the subsequent batch-oriented production of “intermediates” —that is, the interim products needed for the actual medicine— numerous manual inputs are required at the plant; as a result, operating and monitoring systems are everywhere. VisuNet GXP also offers a suitable solution for these scenarios: in addition to an antibacterial membrane keyboard with a capacitive touch pad or optical trackball, it is equipped with a large Full HD multitouch panel, which allows personnel to operate it without any problems even when wearing gloves. According to Seißler, this illustrates how the interaction between human and machine can look in Industrie 4.0 environments: “With the GXP, the qualified personnel are given an operator workstation that is completely tailored to the numerous manual interventions required in the life science sector. Since the RM Shell 4.1, which is a supplement to this, and the additional management tool VisuNet Control Center greatly streamline the commissioning, administration, and support of these operator workstations, there is a double gain in efficiency.”