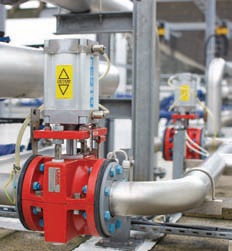

Guernsey Water upgraded their water treatment with membrane filter systems, but after a short time the purging valves caused them a high level of maintenance. A pneumatic pinch valves system now provides high reliability replacements for those butterfly valves. As Guernsey’s only water company, Guernsey Water is tasked with supplying high quality drinking water to over 24,000 households and businesses. Nearly 66,000 people rely on the company’s daily output of about 12 million litres - a figure which rises significantly during the summer months, when the island’s population is boosted by tourists. To maintain this level of supply from a water catchment area of just 43 km2, Guernsey Water operates 16 reservoirs and water storage quarries with a total capacity of 4,425 million litres - about 10 months’ supply - together with three water treatment plants and 409 km of water mains. The water treatment plants are located at St Saviours, Longue Hougue and Kings Mills. The St Saviours and Longue Hougue plants use the latest membrane filters, while the Kings Mill plant, which is only used to meet summertime demand or as a back-up in the event of a failure at either of the other two plants, uses earlier-generation clarification and rapid gravity filtration treatment. The St Saviours water treatment plant was built in the late 1940’s, originally using the chemical coagulation and rapid gravity filters. A substantial upgrade in 2004 led to the introduction of ultra-fine membrane filtration. Membrane filter systems designed for water treatment plants provide a much more compact, higher performance filtration solution than traditional systems using chemical clarification and sand bed filter combinations, and are more cost-effective in use. Most such systems comprise a series of removable modules, each containing a set of fine-tube membranes that allow the passage of water, but which prevent any suspended particulates and biological contaminants from passing through. The impurities are left clinging to the outsides of the hollow-fibre membranes, and are removed by a series of regular purging, or scourging, routines. The membrane filter system at St Saviours comprises four banks of filter modules, together with their associated valves and control unit. It operates completely automatically, using compressed air back-pulses to clean the filters every 15 seconds. When the system was first installed, it performed much as expected, ensuring a high flow rate of quality drinking water for distribution to Guernsey Water’s customers and load-balancing service reservoirs, with minimal maintenance requirements. However, after about 18 months’ operation, the system’s purging valves began to fail, resulting in much higher maintenance overheads and unacceptable levels of system downtime. The valve supplier recommended installing an air lubrication system, but this merely served to compound the problem. According to Andrew Benstead, Water production Manager for Guernsey Water, “During a visit to a trade show last year, I happened to mention our ongoing valve issues to an automation specialist, who suggested that I should contact Festo - by then, we were experiencing up to three faults a week; some of these were genuine, while others were being flagged up erroneously due to signaling problems.” After conducting a thorough on-site survey, Festo quickly ascertained that the principal cause of the purging valve problem was the choice of technology. The existing valves were butterfly type units, which typically have an operational life of between 500,000 to 1 million cycles. Given that the membrane filters at the St Saviours plant are purged every 15 seconds, and that each bank of fi lter modules is generally in use for 200 days a year, the valves had actually done extremely well to last as long as they did - they could easily have failed about a year after installation! The St Saviours plant was also experiencing a high incidence of solenoid valve failures, which Festo discovered was caused by water ingress, exacerbated by incorrect valve orientation and inadequate environmental protection. Another problem was that valve wear had damaged some of the actuator drive shafts, leading to errors in their end-position signals which culminated in false indication of operational status. To overcome the principal problem of premature failure of the air-purging valves, Festo recommended that they be replaced with more appropriate technology, in the form of actuator-driven pinch valves. The type specified have a typical operational life of 10 million cycles - equivalent to more than 8 years’ use with the duty cycle employed at the St Saviours plant. Festo also recommended using non-contact end-position sensors on all the pinch valves, to eliminate the effect of drive shaft wear, and the installation of a suitable cabinet to help keep the solenoid valves clean and dry. Further refi nements included removal of the unnecessary air lubrication system, the addition of a number of Festo quarter-turn actuators and switch boxes, a new 10-inch butterfly valve for water fl ow control, and an additional high performance silencer to further reduce the sound of exhaust air. Guernsey Water decided to adopt all of Festo’s recommendations, but to try them on one of the four membrane filter banks first, before proceeding with the other three if the results proved satisfactory. Most of the hardware was installed by Guernsey Water’s engineers, while Festo provided assistance with air connections, wiring - including connection to the site’s PLC - and commissioning. The work was completed in July 2008. Andrew Benstead is more than pleased with the outcome, “Aside from a minor signalling issue back in September, which Festo promptly resolved, everything has worked flawlessly since switch-on - we have experienced no faults whatsoever - which means that maintenance overheads at the St Saviours plant have reduced significantly. In fact, we were so impressed with the system’s performance that at the beginning of this year we ordered replacement valve systems for the other three membrane fi lter banks, and work is just about to start on installing these. We are also delighted to report that the new silencer system that Festo installed has restored peace to the neighbourhood!

Pneumatic Pinch Valves for Self-Cleaning Membrane Filters

Guernsey Water upgraded their water treatment with membrane filter systems

- by Festo AG & Co. KG

- October 1, 2009

- 379 views