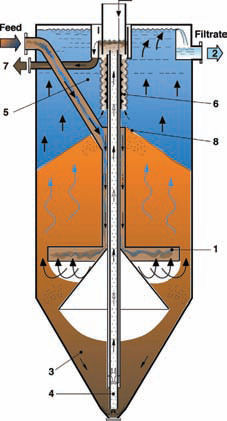

A city in the north of England needed to increase its drinking water supply and decided to achieve this by upgrading an existing treatment plant with an innovative method of sludge settlement. Carlisle is a city of around 70,000 on the north west coast of England, just south of the Scottish border. A short fall in drinking water supply for the Carlisle area was identified and a period of consultation, environmental studies, planning and design started. The resulting scheme involved a 18 million Euro upgrade of the existing water treatment plant at Cumwhinton both to increase capacity and to reduce the risk of crytospordium. The flow for the plant is taken predominately by pumped extraction from the nearby Eden River, supplemented by gravity flow from the Castle Carrock Storage Reservoir. The plant has a designed maximum flow of 27MLD (mega liters per day), a minimum of 12MLD and an average flow of 20MLD. Matt Allason, Process Controller at the Cumwhinton plant, explains that, “Currently, the proportion of our inflow is 5 parts from the river to one from the reservoir. Of course, the reservoir water has the advantage that there’s no cost to pump it. On the other hand, it tends to have higher colour from the peaty soils around the reservoir, so, from a quality point of view, I’d prefer river water only.” At the raw water inlet the flow is monitored for pH, colour, turbidity and conductivity. The first stage of treatment is dosing with an Aluminium sulphate coagulant and a Polyelectrolyte flocculant aid to the inflow, plus sulphuric acid to control its pH level. Matt comments that, “pH is probably the most critical variable for efficient treatment - it affects the optimality of the flocc formation. The pH of our raw water here varies seasonally from 7 to 9. We dose the sulphuric acid to bring this down to a pH of 6.1 to 6.6; we aim for the higher figure in cooler weather.” An inlet chamber splits the flow into 3 streams. The three-stream flow moves on to a flocculator stage and then into Johnson Lamella separators, mounted in concrete tanks. These Lamella’s operate as follows: the main structure is a series of parallel plates, tilted backwards, at an angle of 55%, from the direction of flow. This ‘inclined’ configuration of the plates means that every square meter of tank area can provide 10 square meters of settling area, thus requiring only 10% of land necessary for a traditional settlement tank. The units have a patented flow control system, which ensures that the flow is distributed upward and uniformly across the plate assembly. This works by creating a pressure drop in collection channels above the plates, which ensures that the full area of each plate is covered by the flow. As the water flows upward, the floccs and other solids in the water settle on the inclined plates and slide down into the bottom of the tank. The sludge which accumulates at the bottom of the tanks is removed by Zickert bottom scrapers. These work via the principle of the forward and return movement of wedge shaped, concave sections: the concave sideof the scraper bars acts like a bulldozer to push the sludge forward in the direction of a sludge pit, during a slow forward movement. The scraper bars are attached to flat steel, ‘drawing’ bars, which rest on polyethylene slides. The scraper movement is generated by an electric motor which in turn is connected to the drawing bars via a lever system. On the return movement (which is twice as fast) the wedge-shaped section of the scraper slides under the sludge layer, without disturbing the sedimentation process. From the Lamellas, the clarified water moves onto rapid gravity, dual media sand filters and then to a contact tank where chlorine gas is dosed as a disinfection stage. Sodium Hydroxide is added to raise the final water pH to 7.5. After final measurements of levels of pH, chlorine and other monitoring to ensure compliance with all legal requirements, the main flow is supplied by gravity to the city of Carlisle and surrounds, while a smaller flow is pumped to the community of Caldbeck. The sludge removed from the raw water Lamellas is directed to a second, sludge disposal treatment process at the plant. This is designed to dewater and thicken the sludge to the maximum extent. Water extracted from this process is fed back to the raw water inflow to the plant, while the thickened sludge accumulates in two holding tanks awaiting road transport from the plant to be further de-watered. One of the main stages in this second, sludge washwater treatment process, consists of two additional Lamella separators, though in this case housed in roughly conical steel containers, with sludge hopers at the bottom, and thus having no need for the bottom scrappers required in the rectangular concrete tanks of the raw water Lamellas. Mat describes these units as, “superb! The great advantage of the Lamella units is that they are so much easier to operate and maintain than the settlement equipment we had here at Cumwhinton before the upgrade in 2004. The main problem was the regular ‘drain-down’ which we carry out approximately every three months. We take the units out of the process drain them out and wash away accumulated sludge and other debris. If we don’t do this the process performance will decline.” Prior to the upgrade, raw water settlement employed a method known as ‘Upward-Flow, Flat-Bottom, Flocc-Blanket Clarification’. Here, following flocculation, the inflow entered a rectangular tank from a series of inlets at the bottom. This upward fl ow lead to the formation of a flocc blanket suspended below the surface of the water. The blanket moved gradually, over a separating wall, into a sludge pit at the far end of the tank. “The big problem with this system was restarting it after a draindown: the sludge had to reform before the system was effective again and this could take a very long time - anything from two days to two months. With the Lamellas, restarting is reliably achieved in, at most, a matter of hours. In addition, the actual cleaning out process is a lot easier and less labour-intensive, especially in the wash-water Lamellas, where thanks to the sludge hoppers at the bottom, it’s very quick and easy to hose down the unit and drain all the waste out at the bottom.”

Water treatment with inclined-plate lamellas

A city in the north of England needed to increase its drinking water supply

- by Nordic Water Products AB

- April 12, 2010

- 342 views