Smart RFID labelling enables industry 4.0 efficiencies in identification and management of components, products, machinery and tools. The scope of efficiency savings generated by RFID identification may be realised at several company levels from manufacturing to customer operations. Brady leverages all of its capabilities as a worldwide identification expert to deliver custom RFID solutions that solve our customers’ identification challenges.

Discover Brady’s complete RFID solution

Your tailored solution that includes an RFID label designed for your environment, up to an automated RFID system.

- RFID labels: Custom shaped, printed and programmed and ready to apply or ready to be finalised at your premises.

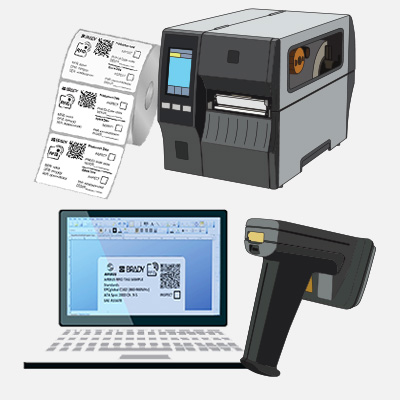

- Print at your premises: Programme, print, serialise or finalise custom RFID labels at your premises.

- Capture data: Capture data from or add data to your RFID labels from a few centimetres in HF/NFC up to 16 metres in UHF, not limited by line of sight.

- Integrate & automate: Automatically capture data from your RFID labels at programmable intervals with fixed scanners, and send the data to your ERP-system.

We can assist you in finding the right combination of products to solve your identification need.

Download the Guide “An RFID solution for your needs”

And how did other companies benefit?

Read our case study “Drive forklift picking efficiency with RFID labels”:

Challenge: Increase forklift picking efficiency

Internal logistics control is still often based on pen and paper and print-outs from WMS and ERP. These time-consuming procedures cost a lot of money, have numerous disadvantages and entail inefficient operations, such as the incorrect placing of products and random driving around of forklifts. So how to get rid of these, while staying in control of ongoing operations?

Solution: Custom RFID labels and integrated forklift scanners

RFID can help locate forklifts quickly. Location detection can take place in real time and continuously, or at crucial places such as zone changes, or when items are scanned, picked up and dropped off. The data generated enable pick-up and drop-off location control, efficient route calculation and route registration.

On top of that, forklifts can also be equipped with detection equipment to read RFID packaging labels on your warehouse pallets, boxes or containers. Brady can supply its L-2588-26B UHF packaging RFID label with a modifiable read range up to 10 metres. They can be programmed on-site with an RFID print-and-program printer, which also enables adding a barcode or serial number on the label. Fixed RFID scanners can be set up to detect the entire inventory, and these data can be sent automatically to an asset management software linked to the company’s ERPsystem. This equipment enables automatic scanning and registration of the articles or load carriers carried along such as pallets, boxes and containers. Manual scans, and the resulting frequent forklift stops, are avoided, and drivers can fully focus on driving.

RFID forklift track & trace solutions enable an accurate and up-to-date overview of internal logistic movements through automatic location and load control. Through registration of routes, you are able to organise your rides as efficiently as possible.

Results: Smart forklifts

Smart forklifts support flawless and efficient order picking and considerably reduce the number of inventories. The technologies used are RFID location detection, automatic load control, wireless communication and control of the drivers through a panel PC with touch screen. These technologies can considerably increase the efficiency and effectiveness of any large warehouse with forklifts.

Contact Brady Corporation to discuss your specific needs & requirements >>