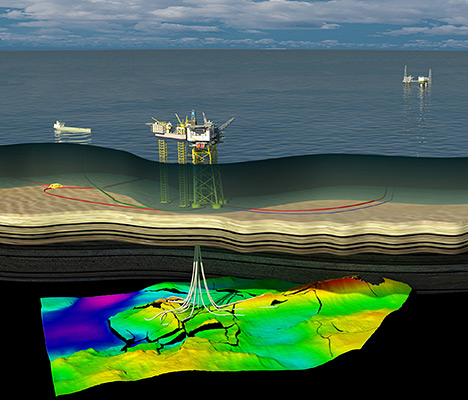

Remote continuous equipment monitoring on a new fixed platform in the Norwegian North Sea will allow personnel onshore to monitor the platform’s critical and essential pumps, compressors and other mechanical equipment, to maximise efficiency and identify potential problems before they affect production.

Statoil is an international energy company with operations in 33 countries. Building on 40 years of experience from oil and gas production on the Norwegian continental shelf, they are committed to accommodating the world's energy needs in a responsible manner, applying technology and creating innovative business solutions. The company is headquartered in Stavanger, Norway with approximately 23,000 employees worldwide, and listed on the New York and Oslo stock exchanges.

Statoil has awarded Emerson Process Management the contract to supply an integrated condition and performance monitoring system for the Gina Krog oil and gas platform in the Norwegian North Sea. The system will enable Statoil personnel onshore to continuously monitor the new fixed platform’s critical and essential pumps, compressors and other mechanical equipment, in order to maximise efficiency and identify any potential problems before they affect production.

Emerson’s integrated Condition Based Maintenance solution provides machinery protection, prediction and performance monitoring of all critical and essential assets. The solution will include Emerson’s CSI 6500 Machinery Health Monitor and AMS Suite predictive maintenance software. This solution will deliver predictive diagnostics as well as equipment health alerts to allow personnel to take timely corrective maintenance actions to avoid unplanned shutdowns and maintain production while reducing maintenance costs.

Central to this solution is AMS Suite: Asset Performance Management, which is built on Meridium’s APM software. The software will aggregate all asset data to present a clear picture of overall asset health and performance so work notifications can be created and fed back to the SAP Enterprise Asset Management system for immediate attention.

The solution also includes a wireless communication infrastructure based on IEC 62591 (WirelessHART) technology, which will support future enhancements to capture additional equipment data on the platform at a lower cost than traditional wired communications.

“As a preferred supplier under our long-term framework agreement with Statoil, we are delighted that our reliability and asset management technologies will be used to support Statoil’s vision for implementing Condition Based Maintenance across its critical assets,” said Larry Irving, vice president, oil and gas industry, Emerson Process Management. “When this is combined with the systems that enable remote monitoring, there are real benefits in terms of maximised production, reduced costs and increased efficiencies.”

This award extends the scope of a previous contract for Emerson to provide an integrated process control, safety and asset management system for the new upstream operations. Located just north of the Sleipner West field in the central part of the North Sea, the Gina Krog field (previously called Dagny) is expected to produce some 60,000 barrels of oil and 9 million Sm3 of rich gas per day.