As we move towards year-end, I’d like to take stock of the current market scenario, while anticipating future trends.

Looking back at 2017

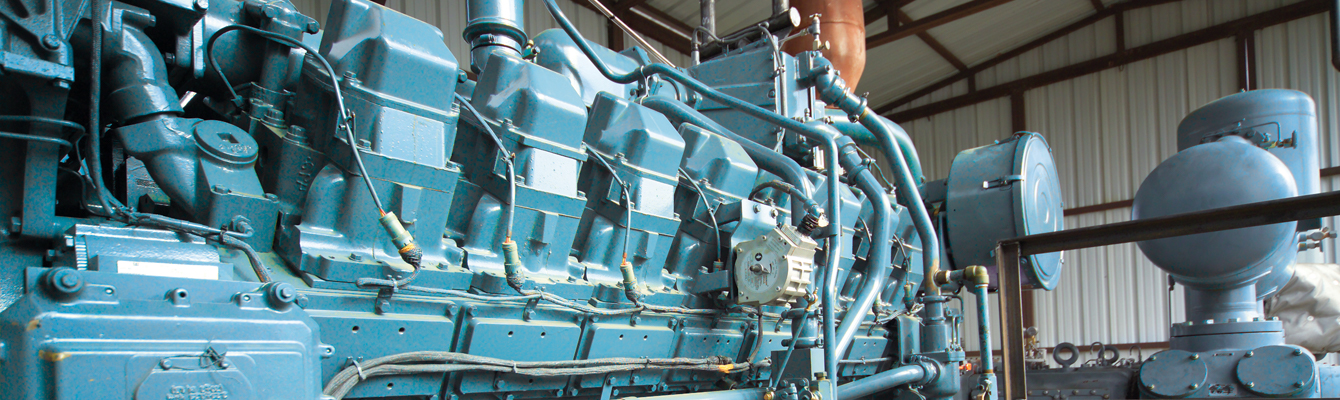

The European Union has a number of initiatives to promote energy efficient operations as we strive for a greener world – and the industry is gradually responding. Gas engines, in particular, are helping to support this mission as a clean energy source with a wide range of applications that can help to reduce waste. As a result, over the past twelve months, gas engine usage has experienced steady growth. This is largely down to the energy efficiencies that gas engines offer, particularly when compared to internal combustion engines.

After all, internal combustion engines remain incredibly inefficient at turning fuel into usable energy, averaging just 20% thermal efficiency. Gas engines, on the other hand, achieve approx. 40% and, in some cases, can reach up to 47%.

Key trends for 2018

I see two key trends emerging as we move into 2018: the rise of dual-fuel engines and changes in maintenance considerations. Dual-fuel engines present a number of advantages to operators for their ability to switch between fuels depending on demand. Typically, a dual-fuel engine will start using diesel and later add natural gas, which ignites quickly, thus helping to start the engine at a high efficiency rate. This adaptability helps optimize engine efficiency to suit specific operating conditions.

When it comes to maintenance considerations, regular checks and care are always important to ensure optimal performance. However, when operating engines on new sources or varying power demands it is essential to monitor performance. For example, there are significant differences in the combustion of diesel engines and natural gas engines, which produce less soot and therefore fewer deposits on engine components. This means longer shutdown intervals for maintenance operations. Developing a routine maintenance schedule is therefore central to enhance the high potential and efficiency of gas engines.

Sara Ibrahim