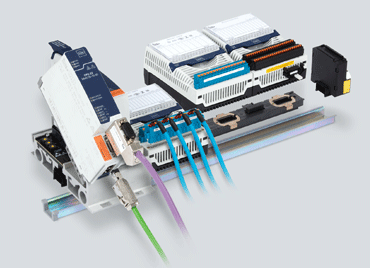

IS1+, the remote I/O system for hazardous areas from R. Stahl, is now also PROFINET-certified, thereby fulfilling all criteria for Conformance Class B devices. Thanks to the support of both MRP rings and S2 system redundancy, IS1+ is suitable for use in applications that place high demands on availability. With the "Dynamic Reconfiguration" (DR) PROFINET function, changes to the configuration, such as adding or replacing I/O modules, can be made online without interrupting communication. Even the CPU (gateway) assembly can be replaced without requiring reconfiguration or additional parametrisation. This feature – known as "Simple Device Replacement" – is yet another addition to the list of PROFINET features. As a "Shared Device", IS1+ is also capable of working simultaneously with multiple controllers.

Protocol-change without change of hardware

As well as PROFINET, the CPU assembly communicates Modbus TCP, EtherNet/IP and the classic PROFIBUS DP fieldbus as standard, including HART transmission and FDT/TDM support for each. The communication protocol can be set by the user, thereby enabling flexible migration and modernisation. This allows a PROFIBUS DP installation to continue operating initially and to be "upgraded" at any time without replacing any hardware by simply switching the CPU to PROFINET, for instance. Communication takes place via a copper cable as standard – with transfer rates of 100 MBit/s with Ethernet and 12 MBit/s with PROFIBUS/DP. In addition, media converters and switches are available to establish fibre optic networks with a reach of up to 30 km.

All components up to the power module feature the usual IS1+ intelligent diagnostics function for proactive maintenance. If maintenance is required, this is detected up to twelve months in advance, indicated locally by a blue LED and reported to higher-ranking systems with a "NAMUR NE107" message. The remote I/O system is suitable for use in extreme ambient temperatures from -40 °C to +75 °C and can be mounted horizontally or vertically. The comprehensive range of I/O modules makes it possible to connect intrinsically safe, non-intrinsically safe and even pneumatic field signals.